Traditional Binding

With various new technologies and innovative ways to achieve beautiful print products, it is important to remember that traditional binding can create stunning results. We are true believers in crafting memorable brand impressions.

Despite contrary beliefs, a book is judged by its cover. And that is why a beautifully created product is essential when presenting printed material to a client.

Our traditional binding techniques are completed with meticulous attention to detail. Here are the four most common methods.

PUR binding

PUR binding involves a type of adhesive binding that glues pages together. During this binding process, a thin layer of adhesive is spread across the spine. A paper cover is then folded over the top to create a finished product.

This type of traditional printing is commonly used for binding books, magazines and brochures and ensures a strong and durable finish.

Saddle stitch binding

Saddle stitching involves folded sheets that are gathered, one inside the other, and then stapled through the fold like using wire staples.

The staples pass through the folded creased from the outside, clinched between the centre pages. Usually, two staples are used, but larger printing may require more staples along the spine. The staples used come in a range of colours.

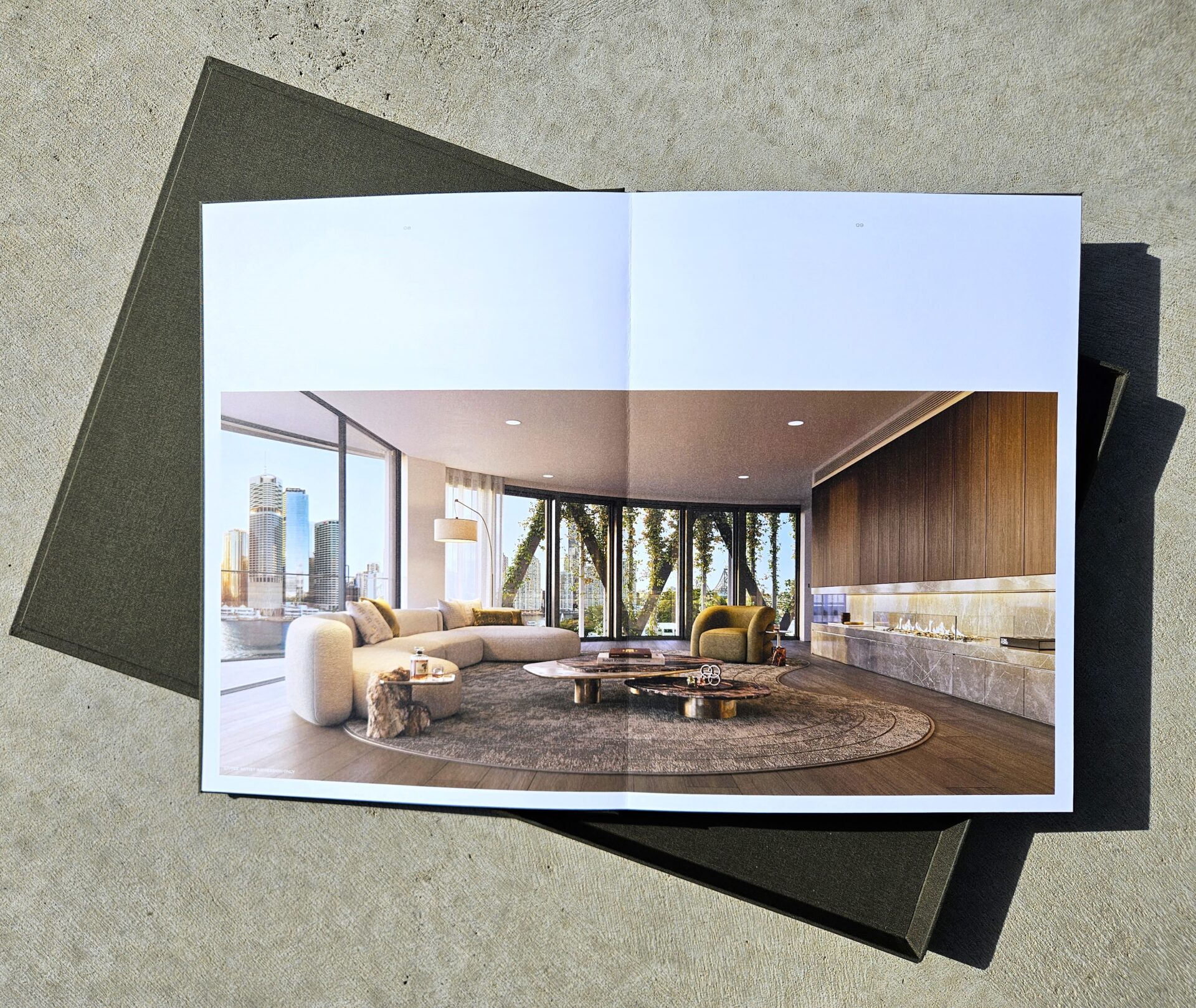

Case binding

Case binding uses varying thicknesses of board. This is usually covered in a variety of specialist materials or paper to create a hardcover or brochure.

Board weights for case binding normally range from 1500mic to 3000mic.

Centre or side sewing

This method of machine sewing involves sewing through the fold of a single section brochure. This is achieved by using an industrial sewing machine. Its thread is available in a range of colours.

Our blog, Traditional Book Binding Techniques, looks at each of these traditional binding methods in more detail.

Recent projects

Enclave by Graya

The Honours

SOL by Walker

51st Avenue

Chatswood, Grand Residences

Maison, Broadbeach

La Belle Penthouse

New Central Boxes

Regency House

Fernhurst

Oakmont Signature Collection

Rivière by Castle Group

Perspective Helm …..

Lexpol Group

Kokomo Private Island Fiji

Secret Garden Books

Harbour Shore Layflat Brochure

Tydal, Woody Point

Quartet Project Books

The Newland Project Collateral

Isabel Hardcover Books

The Grande

Bronte Collection

SOLA Softcover Book

Burly Residences

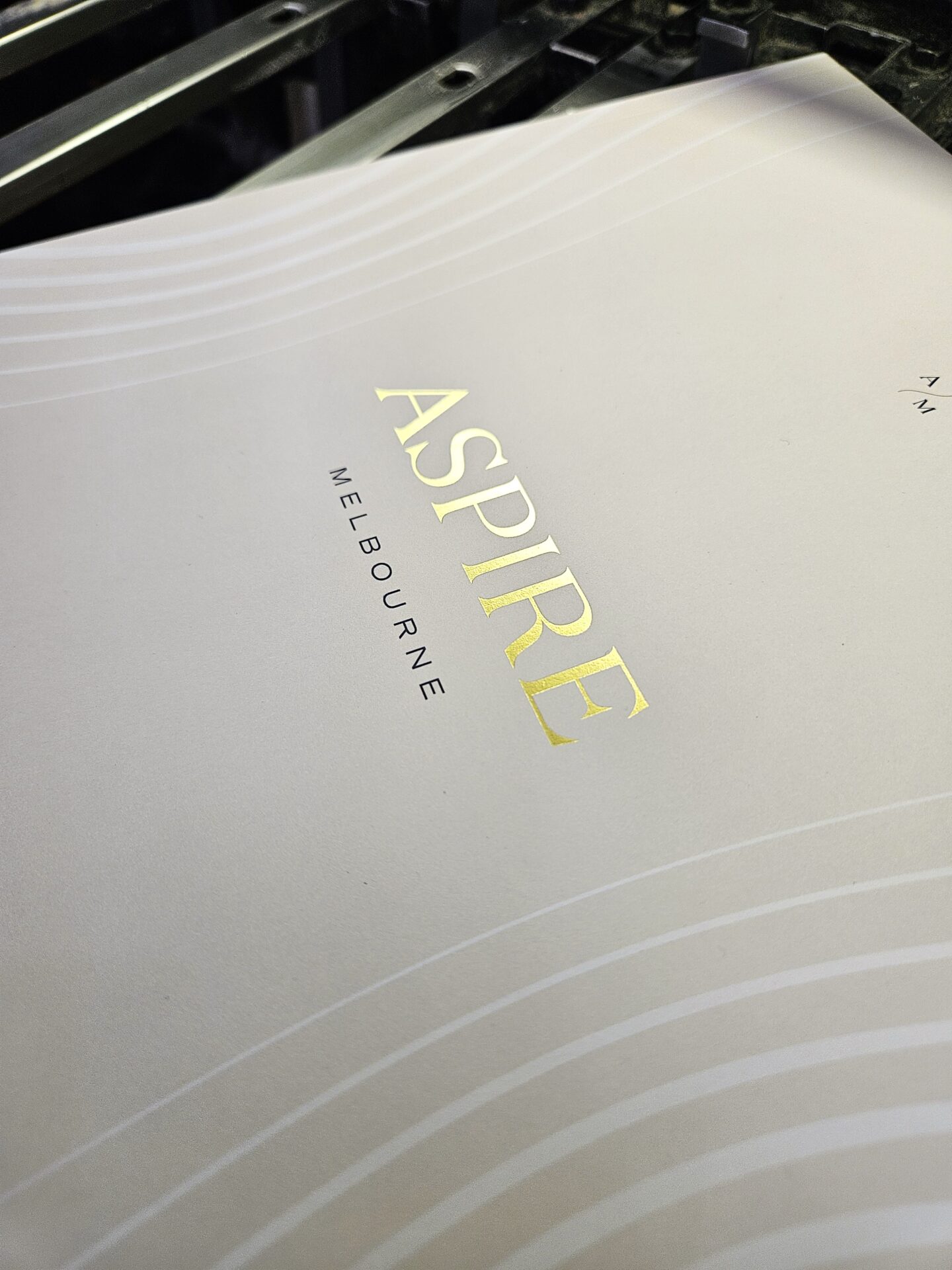

Aspire Melbourne

Trellis Art Books

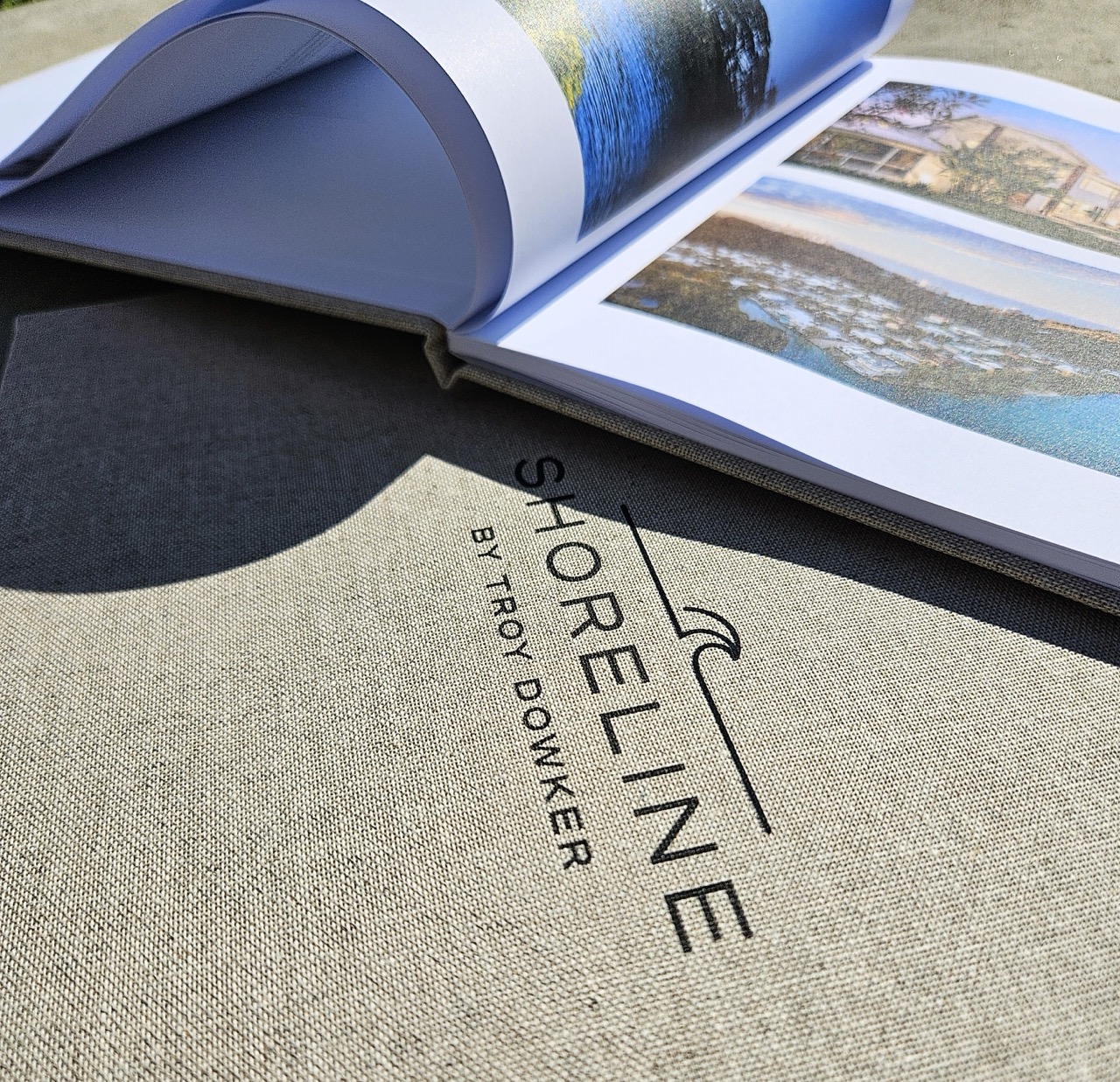

Shoreline Hardcover Brochures Project

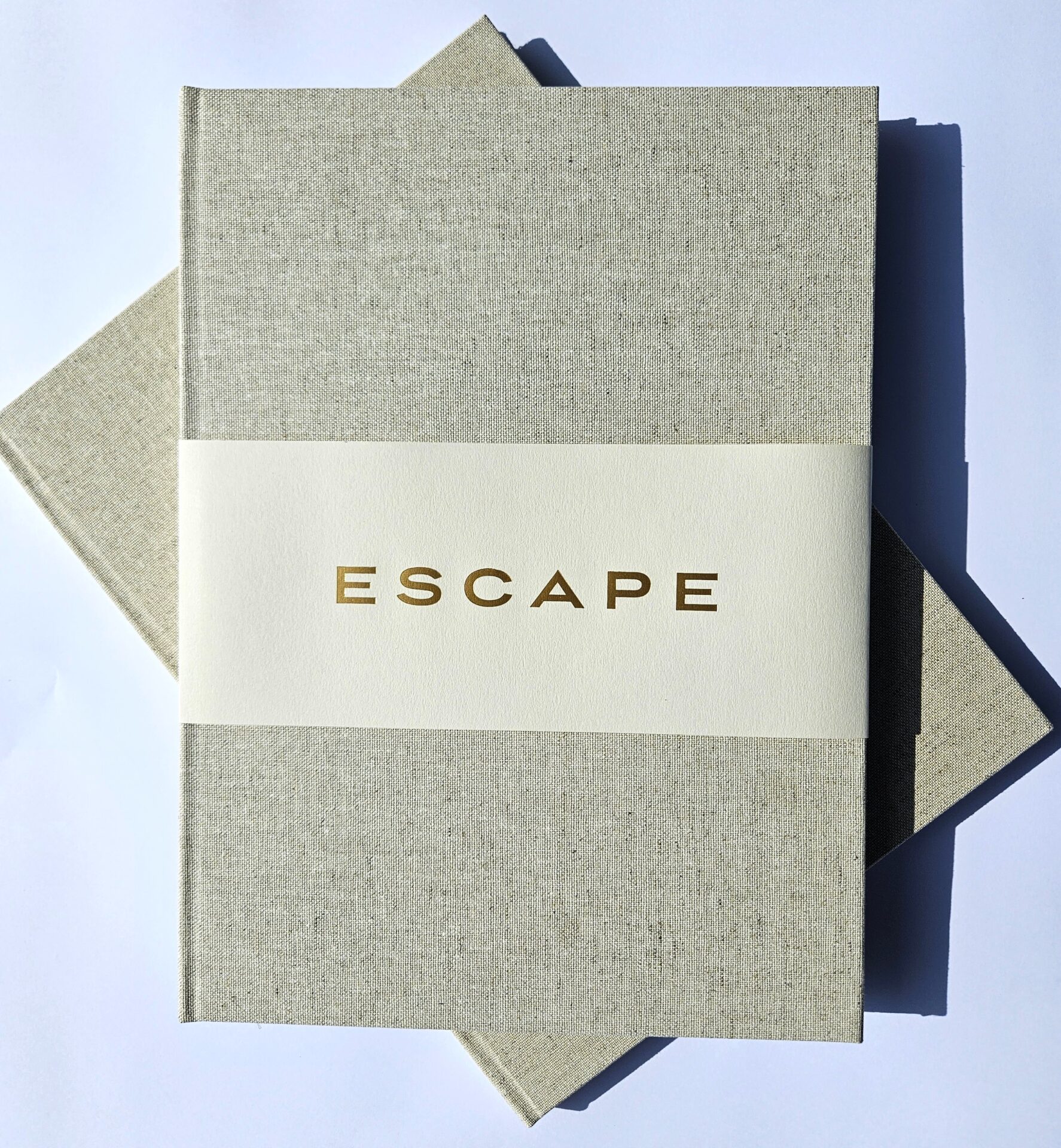

Escape Project

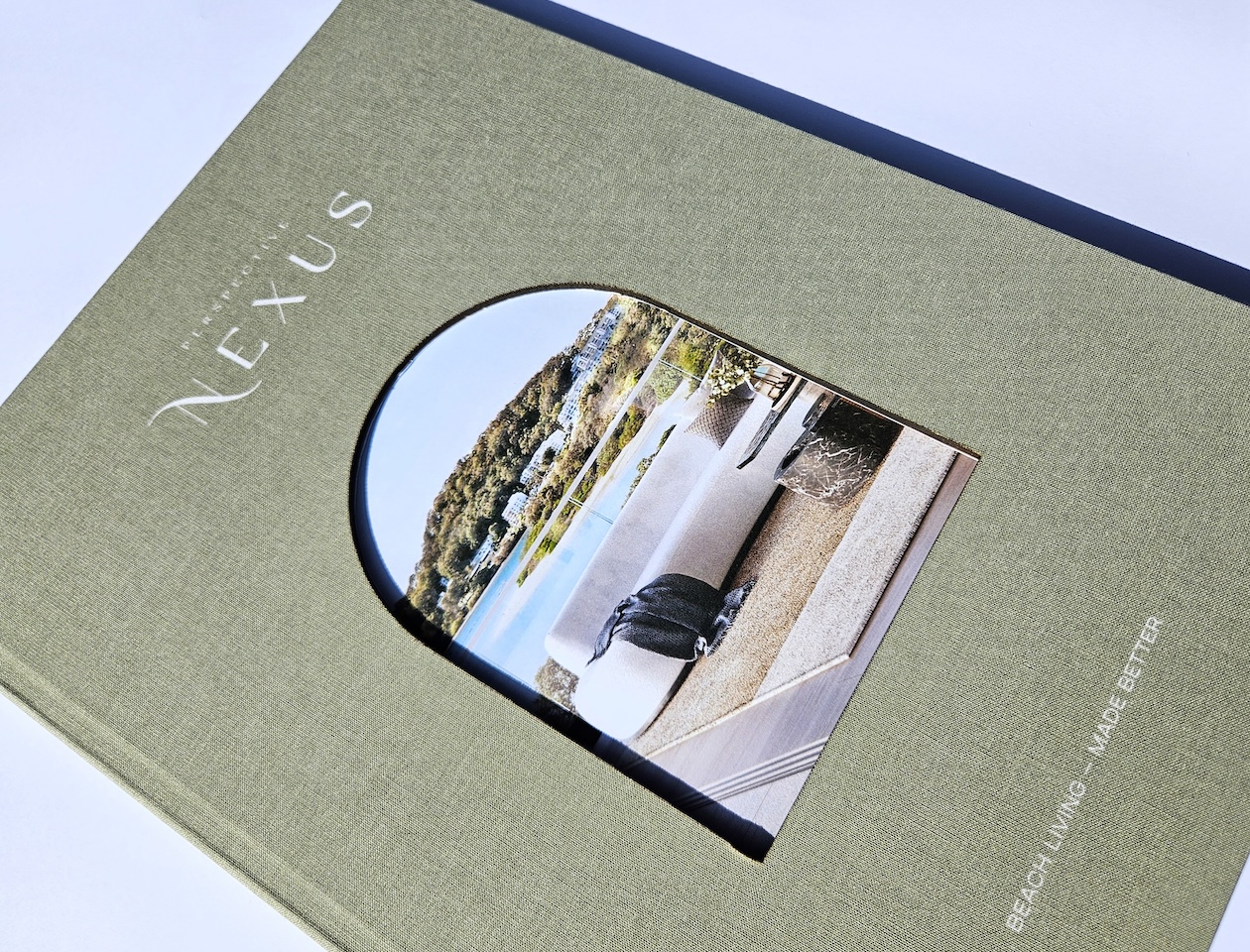

Perspective Nexus

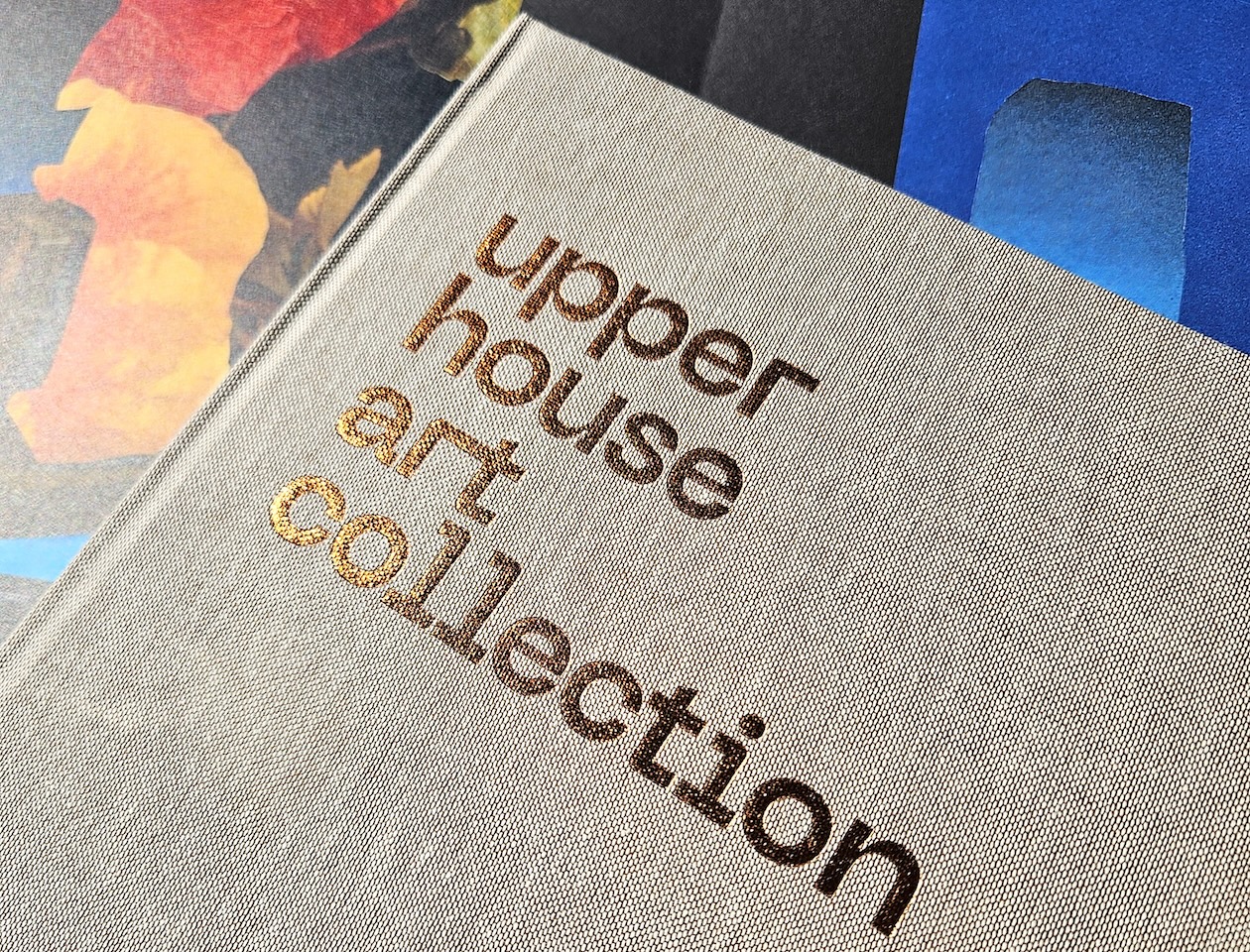

Upper House Art Book

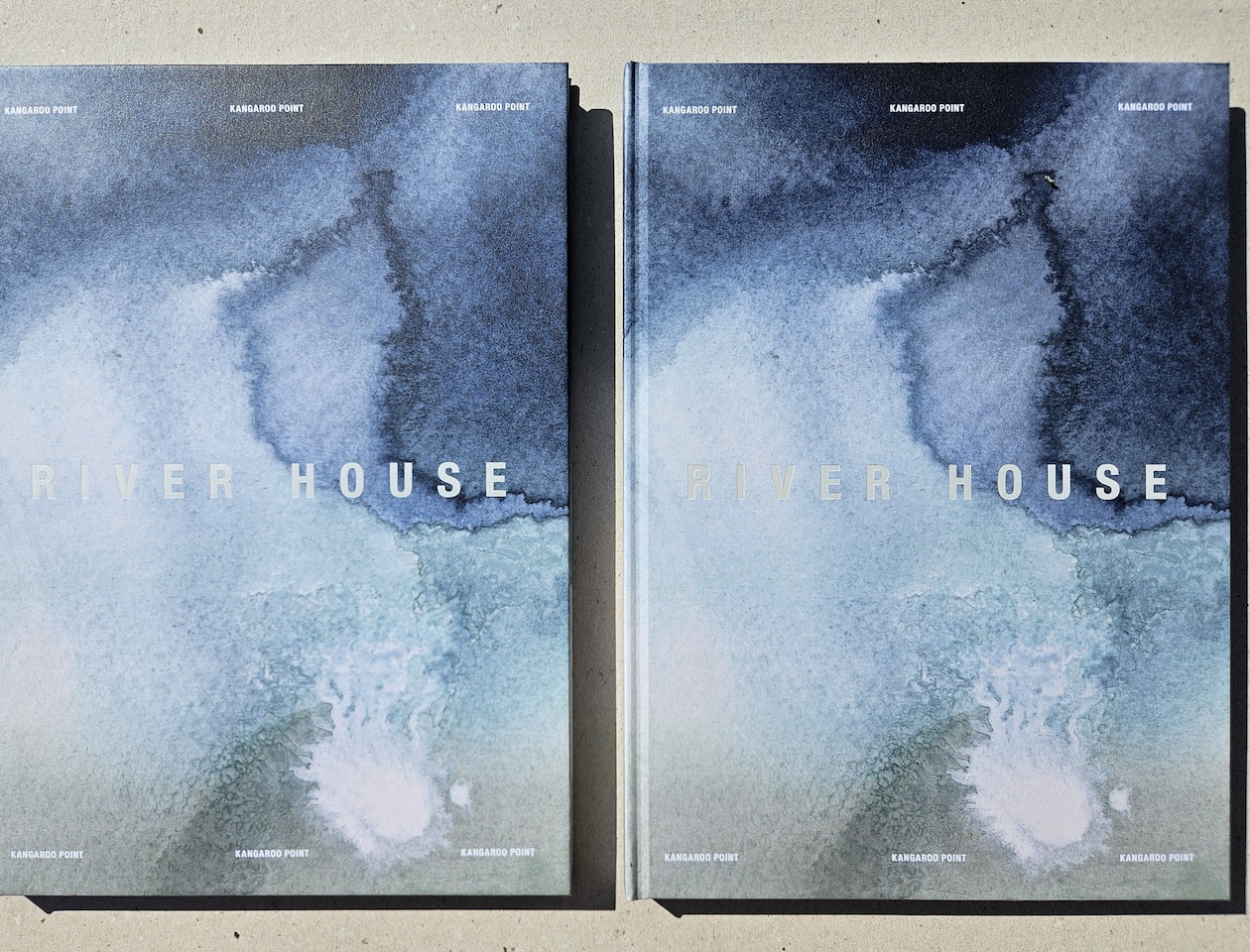

River House

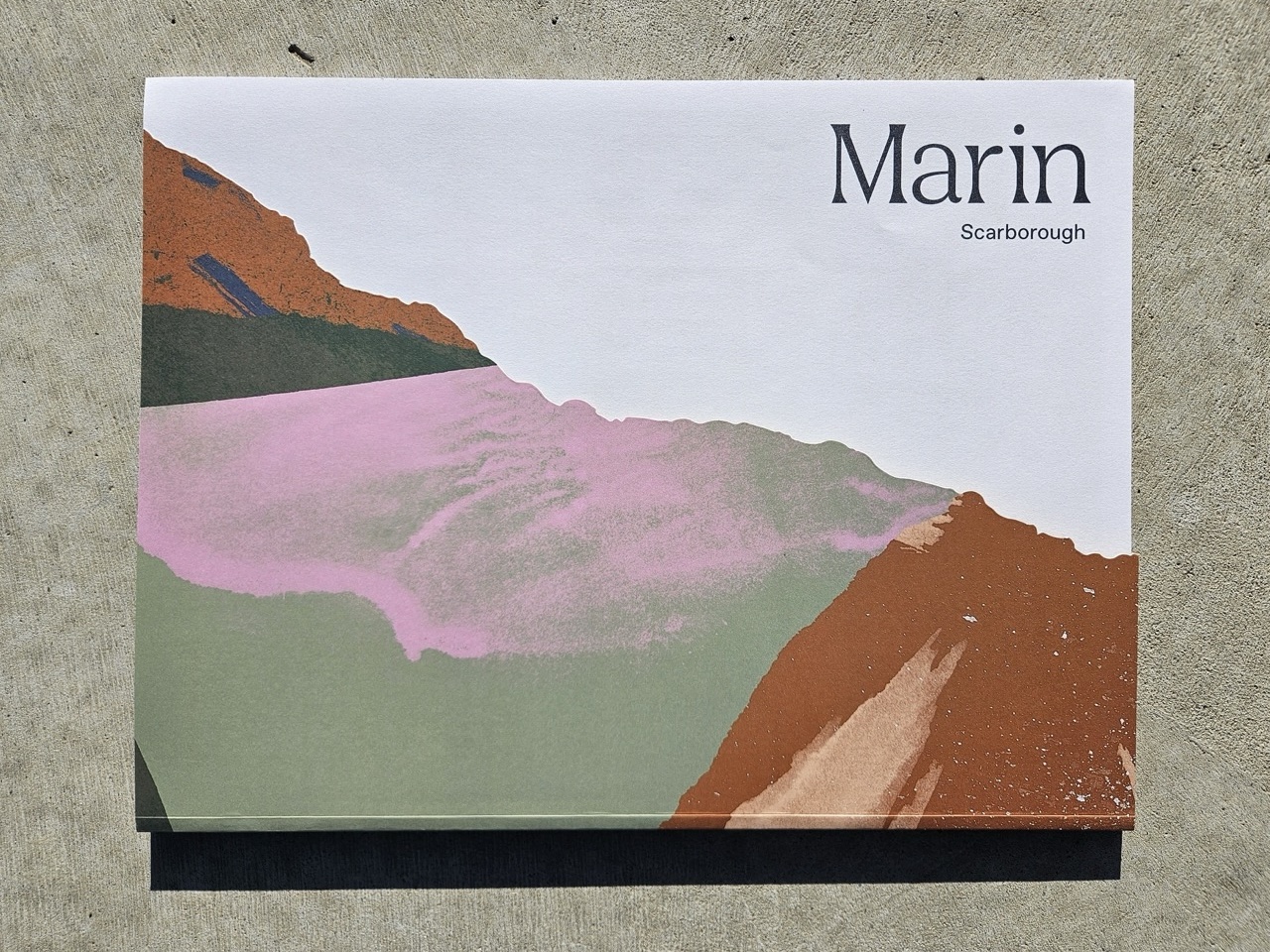

Marin, Scarborough

Ruby Ruby Launch Brochures

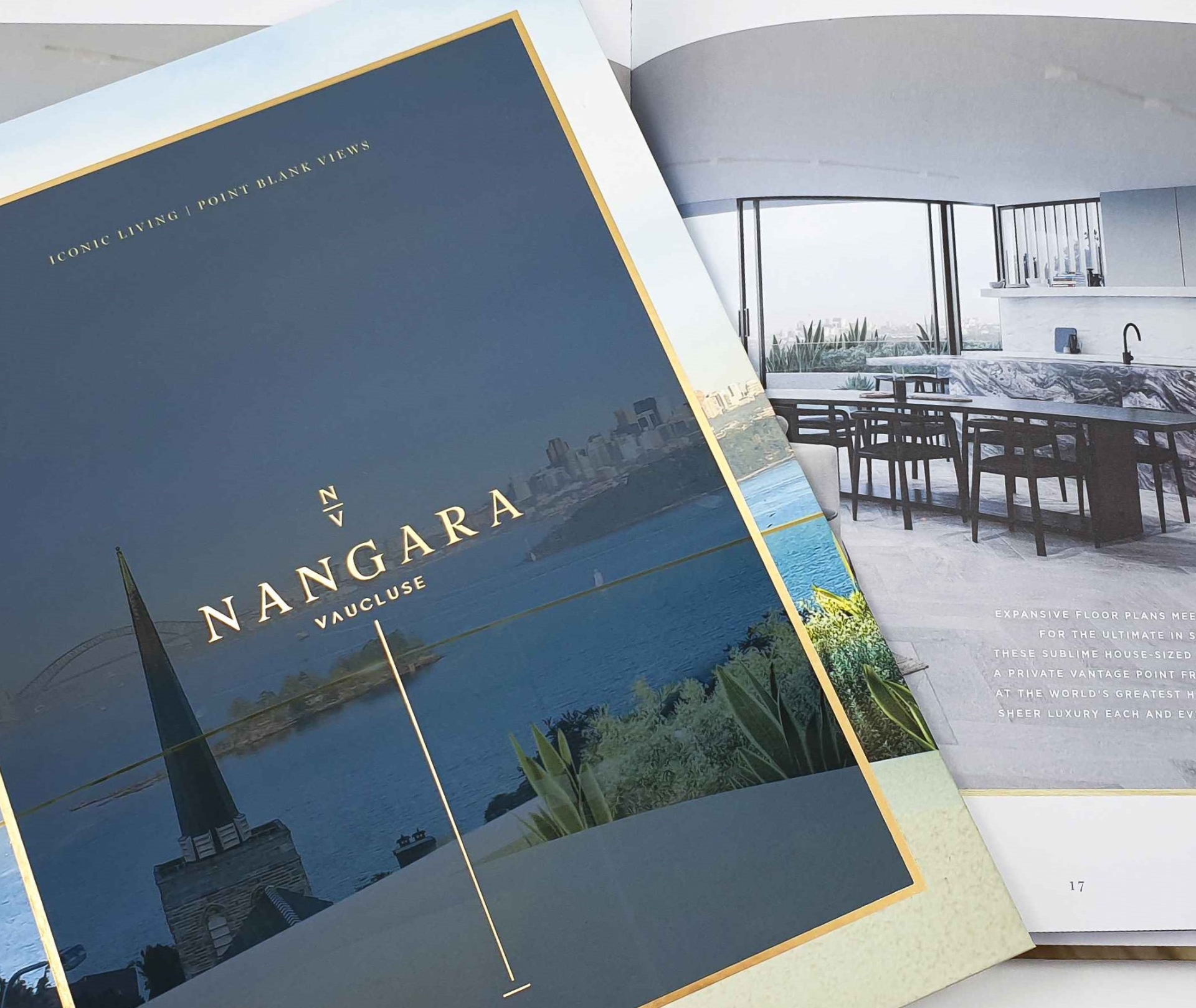

Nangara Hardcover Books

Presenting Sorano House: A Masterpiece of Unparalleled Luxury

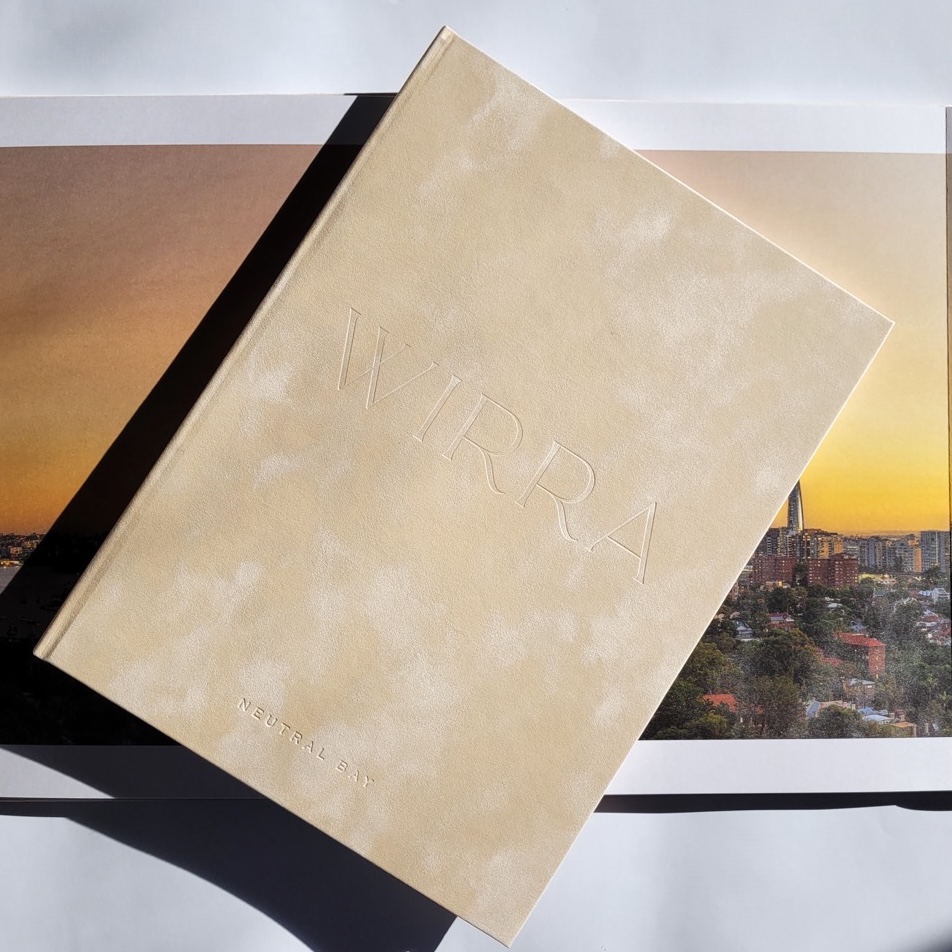

Wirra, Neutral Bay

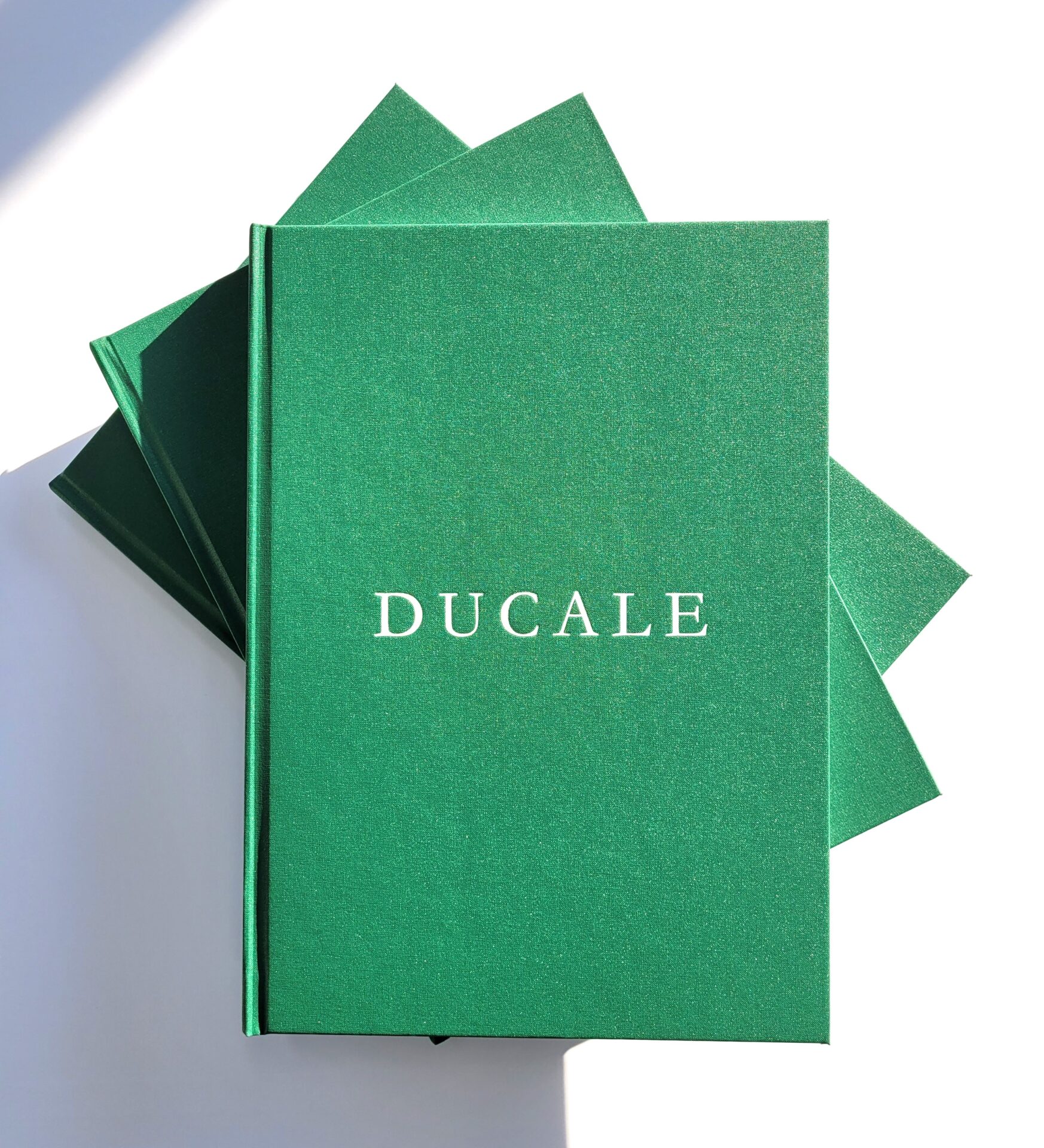

Ducale Project

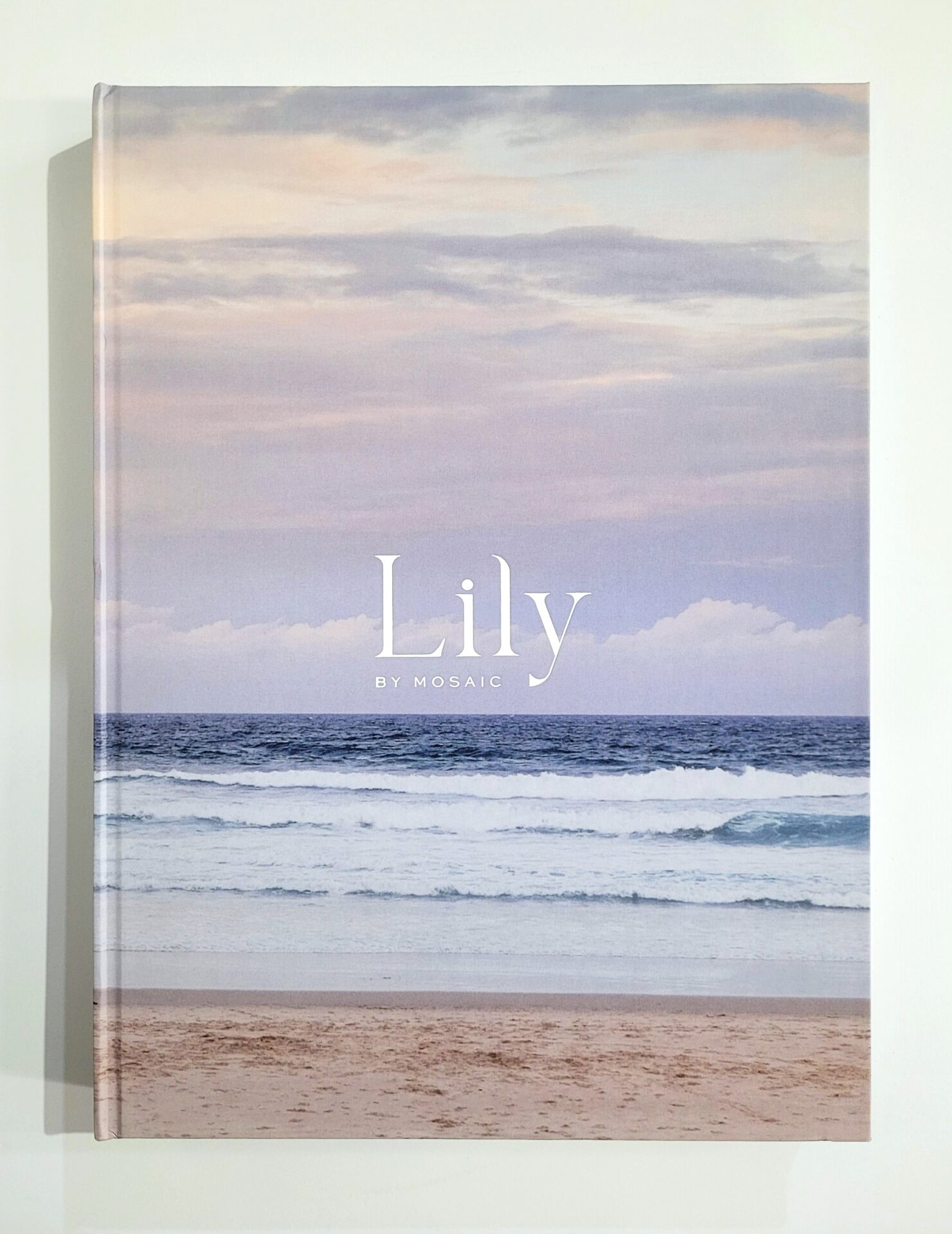

Lily – by Mosaic

Elevating Luxury: Introducing our Bentley and Rolls Royce Invites

Canvas at Bonnyrigg

Sapphire by the Gardens

Meriton – The Triguboff Legacy

Atelier – West End

Diavik Midnight Sun, Musson

MONA, Rose Bay

Union Taringa

Fitzroy Fitzroy

The Mowbray

Paspaley Pearls

The Penthouse

ATLAS By Fortis

111 Castlereagh Street

Campbell’s Stores

488 Perspective

Rosebery Engine Yards, There Agency

The Patterson

Long Pocket

Argyle, New Farm

Are you looking for beautiful traditional binding?

We can help you find the right solution for your project! Contact us today to learn more.